Running on nothing more than Subway sandwiches, donuts and pure adrenaline, EvCC’s Rocket Team raced to complete their high-powered, 30-pound rocket.

After nine long months of sweat, tears and carbon fiber particles everywhere, the team was finally at the test launch site. Ready to see if their hard work paid off, their goal of reaching an altitude of 4,500 feet was ever present in their minds.

As the day unfolded, however, the threat of not launching at all loomed overhead. Every other school’s rockets were shooting off in the air, but EvCC’s team was still working tirelessly — adjusting and readjusting, hammering and drilling. After a four-hour road trip and an additional six hours of working, the launch site was about to close for the day. They were still nowhere near “ready-for-take-off”.

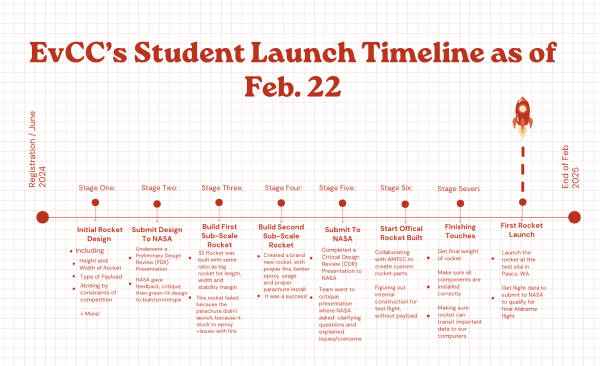

As a subsection of the STEM club, the Rocket Team has been working hard on creating a high-power rocket with hopes of competing in the national NASA Student Launch Challenge. The goal is to “design, build, test, and launch a high-powered rocket carrying a scientific or engineering payload,” as stated on NASA’s Student Launch Page. Once the rockets are built and passed initial testing, there is a final launch in Huntsville, Alabama — home of NASA’s Marshall Space Flight Center.

“This takes the students to a whole new level. Instead of four-foot tall personal rockets, they are designing from scratch and having to dig deep into advanced concepts in rocketry,” STEM club’s faculty advisor Kristine Washburn said. “Plus, the NASA USLI (University Student Launch Initiative) is meant to mimic NASA’s own engineering process, so it’s good professional experience for them.”

But what makes EvCC’s involvement so special? Out of 71 teams nationwide — only two community colleges have been selected to participate in the challenge, EvCC being one of them. With competing institutions that include Georgia Institute of Technology, Massachusetts Institute of Technology and 68 other universities, EvCC is now part of an elite group and the competition is as tough as it gets.

However, the Rocket Team was up for the challenge. The first stages of the design process started last summer after their previous attempt at building a high-powered rocket veered off course (literally and figuratively). They went back to the drawing board looking for things to improve.

There are three main goals the rockets should achieve: The rocket must be stable and fly straight above, reach an apogee altitude (the highest point in the trajectory of a rocket) of 4,000-6,000 feet and descend in less than 60 seconds.

“In a nutshell, the process to develop a rocket is to design a rocket, NASA critique, improve/small changes, build a small rocket, test, NASA critique, improve/changes, build a big rocket, test, NASA critique, competition day,” Bao Tran, one of EvCC’s rocket designers, said.

As if it couldn’t get more complicated for EvCC, the team did something few colleges and universities have ever done in this competition — make almost the entire rocket from scratch. The team collaborated with EvCC’s AMTEC, who created the airframe, nose and fins completely out of carbon fiber. Terece Lewis, a student of the AMTEC program and manufacturing lead, created a 6.5-inch diameter tube with a metal mold and used vacuum bay curing to make the carbon fiber body. This process was repeated three times with the three separate 55-inch rocket parts.

“It’s similar to vacuum sealing,” Lewis said. The process involves removing air inside a chamber and “curing” the material through a hardening/drying process.”

“I literally used garbage out of a scrap pile and turned it into a mold,” she said.

After curing for four hours, with much trial and error, the custom-made components turned out beautifully. This saved EvCC extra money and put some “junk” to good use.

The first rocket launch occurred on Feb. 22 in Pasco, WA (yes, four-hour drive from Everett, Pasco). Not everyone was able to go, but ten members went to that initial test flight. The team met at 6 a.m. and left by van fifteen minutes later. There were just a few things to do — making sure the weight was the same as their digital models, checking the center of mass, checking if bolt plates were in their proper places and weighing everything again down to the gram. In aviation, every gram makes a difference.

Since this was just a test launch, they didn’t include the main payload. A payload is the part of the rocket that carries the mission’s primary objective or cargo. In actual NASA spaceships, it might include astronauts or robots. In this case, it’s ultimately the main communicator and data collector. It will (if all goes well) communicate with NASA through radio and signals, relaying to NASA data such as altitude and the internal temperature. It is an essential part of the challenge and a sub-team is dedicated to ensuring it functions properly.

“The payload wasn’t ready for this initial launch. We are still working on it to make it one small circuit,” Ezra Lakew, EvCC’s payload lead, said.

This lack of payload meant that the team needed to make up the weight inside (using either sand, rocks, or styrofoam) in order to be accurate to the online demo. Plus, they had to adjust the rod to make sure nothing moved out of place — no biggie, right?

Two hours and many donuts later they were somewhat ready to leave. The team would still have to make adjustments when they arrived at Pasco, but it was just a few small things and they were good to go. They were desperate to hit the road, as the four-hour ride meant four hours of much-needed rest.

After a long, sleepy drive, the team arrived in Pasco at 12:20 p.m. EvCC was one of the last schools to arrive at the launch site. There were four schools launching that day: Central Washington University (CWU), Washington State University, SmilingTree High School and EvCC.

EvCC quickly got out their table, tools and supplies to begin working on the rocket.

SmilingTree High School shot their rocket before they arrived, and worked on adjustments to potentially shoot again later in the same day. At around 1:36 p.m., CWU shot their rocket with a goal of 5,100 feet. According to a few CWU students, their GPS said their rocket had reached an altitude of 8,000 feet.

EvCC wasn’t phased, as they worked diligently on centering the rods inside the rocket. WSU shot their rocket at 3:07 p.m., and their rocket had stayed completely on course — straighter than a ruler. But EvCC students had their heads buried in their machinery, checking the alignment, drilling, readjusting components, drilling, sanding down and drilling some more.

The launch site closed at 4 p.m. When 3:30 p.m. rolled around, they still had to input the avionics components (including the GPS and Flight Data Recorder — some of the most important parts of the whole rocket), activate the switch flips (which activate everything to make the rocket launch and make avionic components work) and pack the gunpowder in. Basically, a long way to go.

At 3:43 p.m. they were no closer to finishing — and things went wrong with the finger switch. The buzz of sanding, drilling, hammering and bolting felt almost electrifying. The students from other schools gathered around them, continuously asking questions: “When were they launching?” “What’s going on?” “What’s going wrong?”. EvCC Rocket Team members darted all around the table — fetching more tools, getting more component pieces and more screws. The air was thick with tension. Darkening sky and clouds weren’t the only thing looming over the team; the question of “Will we even launch today?” was on everyone’s minds.

After driving four hours and working for an additional six on the rocket, there was no way this rocket wasn’t launching. The next opportunity would be on March 8, but nobody wanted all this hard work to go to waste.

When 3:50 p.m. came and went, the finger switches still weren’t working. Members of the Tri-Cities Rocketeers, who were in charge of allowing the teams to test their rockets, were packing up their tables and equipment. The number of students from other schools dwindled, cleaning up their own spaces and packing their rockets to leave.

“We’re done!” Tran yelled.

As soon as the words were said, members picked up the rocket, and raced to the launch pad. They sped off faster than a rocket.

Once they got to the launch pad, everyone was desperate to set up properly. Was it past 4 p.m.? Nobody was paying attention. Even the members of the Tri-Cities Rocketeers were helping. The excitement was overwhelming. Nobody could stop smiling (the perfect time for a group photo).

At last, the rocket was lined up and set to launch. EvCC students made their way back from the launch site to the safe-viewing zone.

“Everett College, are you ready?” David King, president of the Tri-Cities Rocketeers, asked.

The screams of approval put the sounds of a rocket’s launch to shame.

King counted down from five, and without a hitch, the rocket blasted off.

It kept a steady path straight in the air, disappeared far into the clouds and came down within the 60-second mark. It was magnificent.

EvCC was off to retrieve the rocket, excited to have this huge step done and out of the way.

But as it turns out, that wasn’t quite the case. The transmitter component broke, thanks to one of the wires burning out — meaning no live data was sent to the station (their laptops). This data is necessary to have in order to qualify for the final launch in Huntsville, because it needs to be checked in the Flight readiness review.

Looks like the Rocket Team will see Pasco again on March 8.

This launch wasn’t a loss, however, as students took a lot away from the flight.

There were many things EvCC’s team found which needed improvement, such as redesigning the avionics, installing the battery retainer properly, working on the realignment and discovering that the bolt plates made of wood melted. This caused the plates to indent inward, so the team decided these needed to be replaced with a different material. They also decided to install an external antenna for better communication and better chances of having live data.

“One thing that we really learned is that we should be doing as much pre-work as we can before game day. It really goes a long way when you’re under the gun, because things are already taken care of,” Lewis said. “Working together as a team is really important … helping out even when something isn’t your responsibility … that is really what got us up in the air.”

“Anytime it goes off the pad, I’m happy! That’s the biggest hurdle to overcome… Luckily we have a solid team, and that all the challenges we have come across we will be able to easily solve. We have a great team of engineering students,” Amanda Ellis, the vehicle design lead, said.

“I feel like … we could be more prepared. It was just a test launch, so we were just getting things together. Next time we launch, it won’t take as much time to set up because we will know what we need when we need it, etc. But overall, it was so successful. Everyone put in a lot of work,” Chara Taase, outreach lead for the project, said.

If the launch on March 8 is successful, the team will submit their data and present their Flight Readiness review to NASA, with only a few more steps thereafter.

Although this launch wasn’t quite a “success”, the team learned a lot. With this newfound knowledge, their March 8 launch is sure to reach new heights.

And after that, watch out Alabama — here comes EvCC!