Manufacturing the Future: AMTEC Job Fair

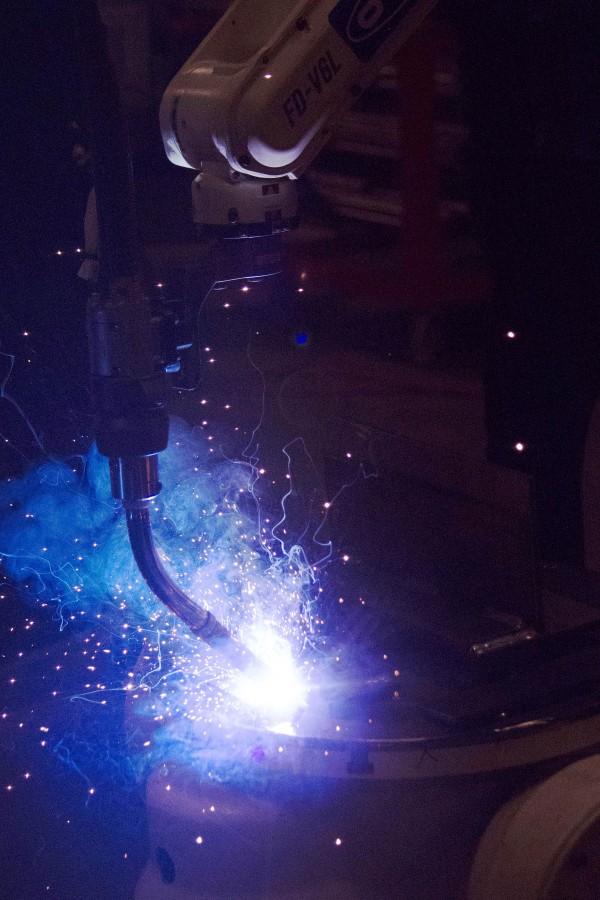

Air Gas’s robotic welding arm in action. Metal name tags engraved with “Air Gas” were submitted to the flame.

Planes, trains and automobiles. What do they have in common? They were made by manufacturers.

EvCC’s Advanced Manufacturing Training and Education Center (AMTEC) opened October 2014. The center offers stackable certifications that build towards obtaining jobs in the manufacturing industry.

AMTEC held a job fair on March 1 for students, graduates and community members to meet employers.

Laura Baker, the employment solutions manager for AMTEC who organized the job fair said, “I think these students are very talented. Most of them are going straight to work.”

Businesses such as Boeing, Vigor and Senior Aerospace AMT engaged with both EvCC students and visitors as they passed. Job fair-goers walked from booth to booth, exchanging résumés and business cards.

Aerospace Ambassador Demri Lewis sat behind the EvCC booth. Before her was a metal bar and fake white crocodile, among other items.

Senior Aerospace AMT recruiter Jeanne Rogers speaks with a student about the company. On the table are lists of job opportunities.

“Everything you see here is applicable to the job field,” Lewis said. She picked up a slab of what looked like cardboard honeycomb and demonstrated its durability by pressing and bending it.

She held up another object, flat and smooth, black in color and dull in sheen. “Carbon fiber,” she said, “easier and lighter than metal.”

Lewis is an EvCC student in precision machining, a program that boasts a hiring rate of ninety percent just 30 days after graduation. “I love it. Every teacher that I’ve run into is really friendly, and they want you to succeed.”

AMTEC students Cody Evans and Patrick Feller agreed.

“I joined EvCC because it’s the only local community college that offers fabrication programs. It’s a great facility,” Feller said.

“It’s pretty laid-back, with ninety percent of it hands-on training,” Evans added.

To those interested in manufacturing, “I’d say to try different classes, there’s lots of places to go. Solidify your skills and invent projects for yourself,” Lewis said.

Arthur Schnitzer, a welding process specialist with Air Gas demonstrated a robotic welding arm, a cell that would be useful for production.

“We’re looking for employees who are ambitious and possess the entrepreneur spirit,” he said.

Arthur Schnitzer demonstrates the power of a robotic welding arm to curious onlookers. The booth was placed out of the way to make room for the machinery.

Schnitzer is an EvCC alumni from the class of 2013, and called Rob White “a very big gift to this program.”

“The staff in the welding department know where their limitations are and aren’t afraid to admit it and show you where to find the answers. That’s important,” he said.

AMTEC is undergoing expansion. Construction will begin in April and will introduce the Mechatronics program in Fall 2016.

Baker is a Kansas State University graduate, but wishes she attended AMTEC.

“It’s actual knowledge you’d use on the job. There’s no question on what you’re doing,” Baker said, “There’s a job waiting for you. Take the time, get the training.”

What interests you about journalism?

The people. The stories. The short sentences. Honestly, I just about love it all.

Where are you headed...